Difficulties in Scale Up of Nanomaterials

Nanomaterials are essential to nanotechnology and nanoscience. It is determined by numerous domains such as chemistry, physics, biology, engineering, material science, computer science, and so on. Nanomaterials are defined as having at least one dimension in the range of 1-100 nanometers. A nanometer is one billionth of a metre, or 1 nm = 10-9 m, while a micrometre is one thousandth of a millimetre, or 1nm = 10-3 m. The thickness of the paper is 100000 nm, which indicates that the nanometer is 100000 times smaller than it. Because this scale has a variety of unique qualities that have applications in a variety of disciplines such as paints, medicinal treatments, chemical catalysis, and so on. It has a huge influence that will grow in the future.They are important in industrial and academic research because of the unique properties that result from their small size and high specific surface area. However, when nanomaterials were scaled up for mass production in the past, they encountered a number of technological and financial challenges.

The Significance of Nanomaterials in Various Industries

Many disciplines and industrial areas, including information systems, national security, health, communication, power sector, food security, and climate change research, have been significantly enhanced, if not reinvented, by nanomaterials.

Nanomaterials facilitate the production of reusable, long-lasting "smart fabrics" fitted with elastic nanosensors and processors capable of healthcare monitoring, solar energy collection, and power generation through movement. Nanoparticles are also increasingly being employed in catalysis to speed up chemical processes. This minimizes the number of catalytic materials required to achieve the desired effects, cutting costs and lowering pollution.

Nanotechnology is also expanding the range of medical instruments, information, and medicines accessible to practitioners. Nanomedicine is the use of nanomaterials to provide efficient results for preventive care, diagnostics, and treatment.

Commonly used Nanomaterials in Industry

Metal oxides, particularly silicon dioxide (SiO2), titanium dioxide (TiO2), alumina (Al2O3), and iron oxide (Fe3O4, Fe2O3), are currently the most economically important inorganic nanoparticles used in industry. Metal oxide nanomaterials are used in electronics, pharmaceuticals, skincare, biochemistry, and catalysts. Bottom-up techniques are employed to create metallic-oxide nanoparticles. The elimination of transition metals in dilute solutions is a common mass production technique used for these nanomaterials.

Another nanomaterial used widely in the industry, especially electronics, is quantum dots. A quantum dot is a tiny particle of matter whose characteristics are altered by the introduction of a single electron. Quantum dots are made up of a few hundred atoms of semiconducting material that, when stimulated, produce light at varied wavelengths depending on their size, making them particularly valuable as biological indicators of cell activity.

Gold nanoparticles are widely used in the healthcare industry. Foreign item penetration normally causes cell damage or death, yet these particles may pass through cellular membranes without causing harm. As a result, they are great carriers of medication to normal tissues or radiation to malignant cells.

The most common synthetic technique for producing gold nanoparticles is the reduction of metal salt in suspension with the assistance of a modifier. A wide range of reductants and modifiers have been discovered, allowing for the production of vast quantities of nanoparticles. However, the cost of producing gold nanoparticles is USD$80,000 per gram, while a gram of raw gold costs just USD$50.

Importance and Difficulties in Scaling Up Nanomaterials

There is a need for mass manufacturing of nanomaterials in order to replace existing materials with nanoparticles with superior capabilities. Nanoscience offers a once-in-a-lifetime opportunity to understand physiochemical processes at their most fundamental level. This information, in principle, should be valuable in enhancing and optimising a structure under consideration.

Despite these fundamental breakthroughs, nanotechnology faces enormous challenges. This is due to the fact that translating scientific results published in peer-reviewed publications into industrial technological applications remains a significant difficulty. The problems are complicated.

(I) The properties of nanomaterials change when scaled up, just as they do when scaled down to the nanoscale; especially, the degree of control available at the nanometer scale diminishes at the meso- and macroscales. Many of the characteristics that make nanomaterials appealing (such as their high surface area-to-volume ratio) are also characteristics that make them challenging to deal with. It is frequently challenging to preserve these features when producing nanoparticles on a large scale.

(II) Unless a big return is guaranteed, the industry is unwilling to invest extensively in developing new large-scale procedures for nanomaterial manufacture. The quandary is most acute in applied sciences, where there is a divide between laboratory and industrial-scale research.

(III) When producing nanomaterials on a big scale, it is typically difficult to manage their size and form. This is due to the fact that the manufacturing process frequently depends on 'bottom-up' processes, which include constructing nanomaterials from smaller components. This might result in variances in the final product's size and form.

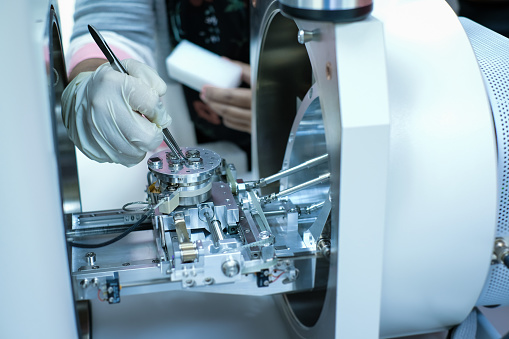

(IV) The cost of production is a challenge that might arise while scaling up nanomaterials. Because of the advanced equipment and procedures required, nanomaterials are frequently costly to create. This can make large-scale production of nanomaterials challenging without incurring considerable expenditures.

Industrial Manufacturing of Nanomaterials Vs Lab Manufacturing

To make nanomaterials in a lab, a researcher must first mix many chemicals, which is time-consuming and labor-intensive. These traditional procedures are utilized to make most nanoparticles used in research investigations in small quantities. Although small quantities are fine for early investigations, they impede the translation of successful innovations into commercial applications.

Despite these challenges, there have been some significant breakthroughs in nanomaterial scale-up. For example, using a 'bottom-up' manufacturing process, a team of researchers from the University of Oxford successfully scaled up the manufacture of graphene - a single-atom-thick sheet of carbon - in 2010. This was a remarkable accomplishment since it revealed that nanoparticles may be produced on a massive scale while retaining their characteristics.

In 2016, a team of researchers from the University of Manchester reported the development of a novel 'top-down' manufacturing technology capable of producing huge amounts of high-quality graphene. This new technology has the potential to create graphene for a quarter of the cost of current technologies.

Leading Technologies for Scaling up Nanomaterials

Cerion, for example, used a process known as DFM, which stands for design for manufacturing. This technology uses a phase/gate strategy to simplify, optimise, and enhance the nanomaterial while avoiding invasions that may stymie scale-up or boost manufacturing costs. The technique addresses all critical commercial, scientific, technological, environmental, supply chain, and logistical factors that determine the ultimate cost of the nanomaterial.

In another innovation, researchers at the University of South California identified an automated production process that can improve on the time-consuming batch approach now in use. The process makes use of 3D-printed tubes with a diameter of only 250 micrometres. The researchers tested four parallel tubes by sending non-mixing substances such as oil and water through each one. Nanoparticle droplets formed at the apertures as the fluids fought to push through the pipes.

The Langer group at MIT developed a method for manufacturing gramme quantities of extremely reproducible lipid polymer nanoparticles every hour. This method has the potential to be a powerful tool for moving nanotechnology toward therapeutic applications. This approach may also be utilised to manufacture a wide range of nanoparticles with a variety of therapeutic payloads.

Conclusion

While there have been some achievements in nanomaterial scale-up, the limitations connected with this process ensure that it remains a substantial problem. To overcome these obstacles, further research is needed to create novel production procedures and expand our understanding of nanomaterial characteristics. and form of nanomaterials when mass-produced on a huge scale This is due to the fact that the manufacturing process frequently depends on 'bottom-up' techniques, which include constructing nanomaterials from smaller components. This might result in variances in the final product's size and form.

Scaled-up manufacturing can be an efficient and cost-effective technique for producing nanomaterials for many industrial uses. To ensure that cost-effective quality materials can be produced, the transition of a nanomaterial from the laboratory to the industrial environment should follow a precisely synchronized method.

Comments

Post a Comment